CIVIL ENGINEERING SUPPORT

Another cost effective use of composites and fiberglass is within the civil engineering sector.

The fact that fiberglass is light weight, requires low maintenance, is waterproof and corrosion resistant makes it ideal for applications such as water tanks, sewage collection plants, pipelines, waterproofing of roofs, FRP sections where corrosion is a real risk, and FRP grating in walkways and environmentally challenging locations. Fiberglass is also being used nowadays as reinforcement bars on non-structural concrete parts.

It has proven to be a cost-effective material in Reverse Osmosis plants, Waste Water treatment systems and fire hydrant systems.

30 years ago the company invested in a filament winding machine, enabling us to efficiently create resilient cylindrical structures for use in tanks, pipelines, cartridge filters and other types of housings.

Below are examples of projects, products and raw material that we can offer in this sector. For more information we invite you to contact one of our professionals to discuss in detail your requirements.

Project specific reservoirs and systems

These are some of our custom-built and use-specific reservoirs and systems:

-

Double-layered chemical tanks - 4m diameter 5.5m height.

-

Sewage collection tank - designed for installation below sea level, 3m diameter 13m length.

-

Oil interceptor system - specifically built for one of our European clients under licence.

-

Silt tank system - specifically built for one of our European clients under licence.

-

Grey water filtering system - built specifically for a local Engineering firm.

|  |

|---|---|

|  |

|  |

|  |

|  |

|  |

|  |

Project specific pipelines and flanges

Having an in-house filament winding machine, it was only natural to go into the production of pipelines and flanges. Over the years the company has perfected the design of flanges, pipes and corresponding joints, adapting for various types of pressures and dimensions.

|  |

|---|---|

|  |

|  |

|  |

|

BWSC Malta power station

One of our most recent projects was the construction of 2 custom-built silt cleaning tanks for turbine chimneys at the local BWSC Power Plant. These tanks were 2.1m in diameter and 13m in height.

|  |

|---|---|

|  |

|  |

|  |

|  |

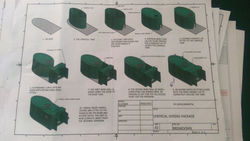

Septic dosing system

This was a collaboration effort with one of our esteemed European clients, demonstrating our prototyping facilities. It all started with a design concept and a list of product goals to be achieved. Following the first prototype, we have now improved on the original design enhancing performance and achieving higher standards. At the same time, we managed to produce a marketable product that met the cost brackets and purposes originally set by the client.

|  |  |

|---|---|---|

|  |  |

|

Linen shoot for a respite home

This is yet another example of a surprisingly suitable application of fiberglass. Our client required a 60cm diameter linen shoot that would cater for all 5 levels of a local respite home. The project involved building a series of access shoots on every level to guide dirty linen efficiently to the laundry.

|  |

|---|---|

|  |

|

Maintenance of floating modules for the oil and gas sector

Recent State and private investments within the oil and gas industries opened up new market opportunities for our company. We are now the leading service provider for maintenance of floatation modules used on offshore oil rigs. As expected, strict protocols needed to be followed, and not only did we manage to achieve the required quality standards, but also managed to satisfy the tight deadlines, with a rate of up to 30 units serviced per day.

|  |

|---|---|

|  |

|  |

Water and sewage transportation

Our filament winding machinery allows us to provide solutions for any type of water transportation. We can cater for both standard configuration of water bowsers and custom-built containment, to suit the clients’ needs. We are proud to say that we have been manufacturing bowsers for over 30 years and our products have outlived the lifespan of the vehicles that were carrying them.

|  |

|---|---|

|  |